WatDig Controls

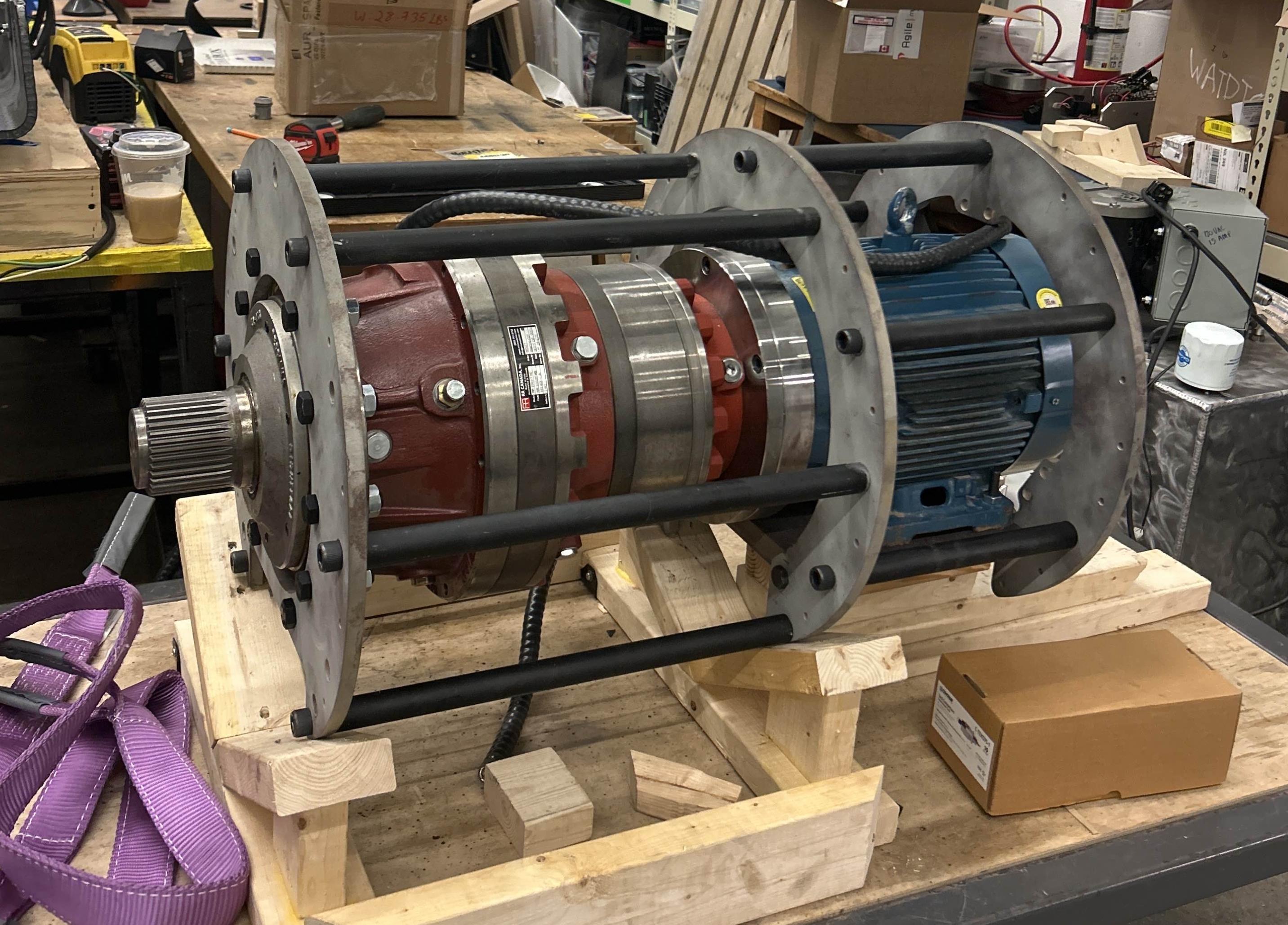

WatDig is the University of Waterloo’s student design team competing in the Not-a-Boring Competition. It is our first year competing in the full-scale competition building a tunnel boring machine (TBM) meaning everything is designed from scratch. I am responsible for leading the controls team. Our team is on track to finish construction by end of year.

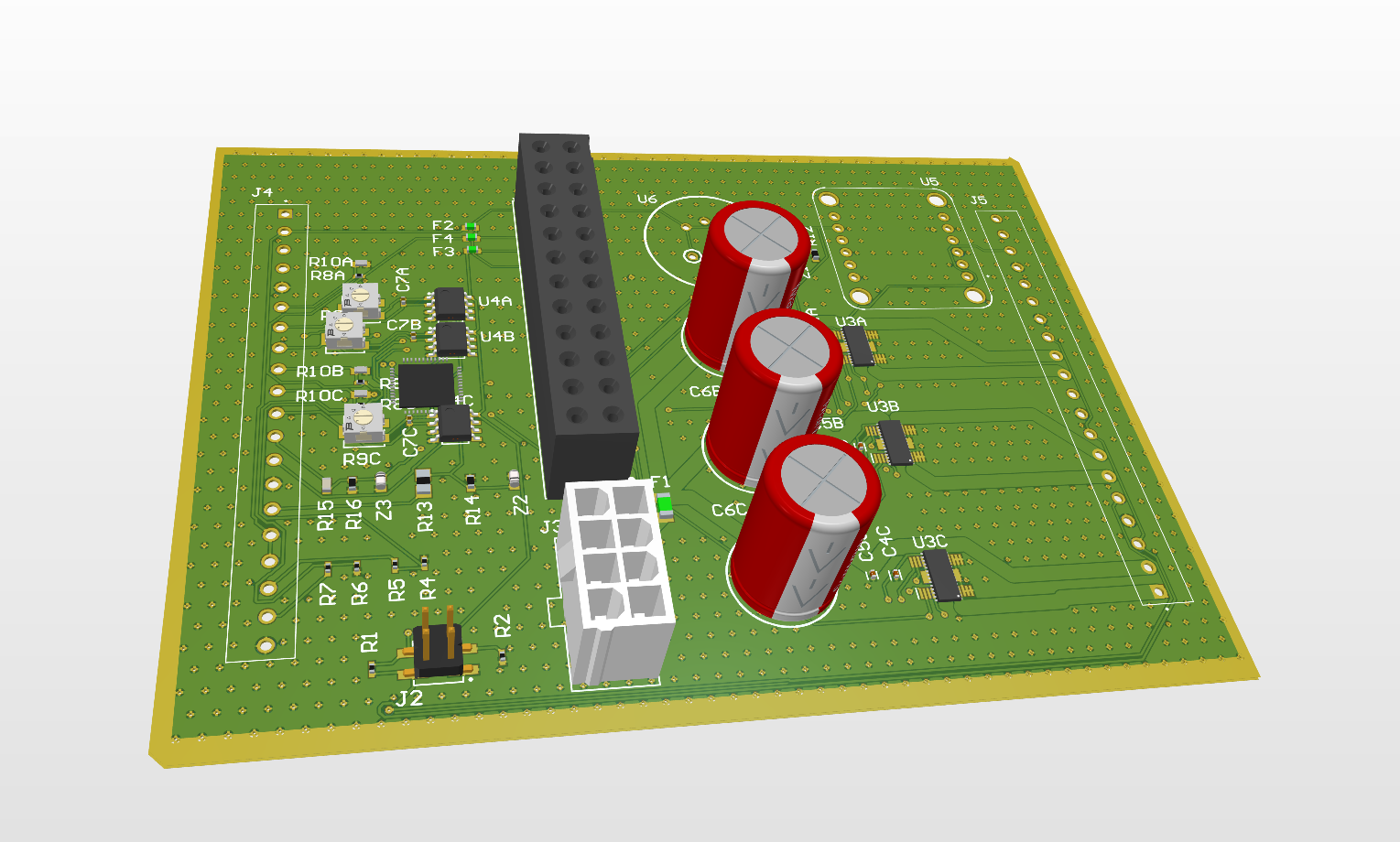

The controls system acquires readings from dozens of sensors and controls actuators on and off the TBM. All sensors and actuators communicate to the control laptop over RS-485 Modbus RTU. Some devices communicate natively with Modbus RTU, such as our ACS550 motor drives and power meters, while the majority rely on custom PCBs to create a RS-485 interface for the sensors and actuators.

The WatDig team has three custom PCBs. The above ground sensor board, below ground sensor board and high voltage monitoring board. Some of the sensors and actuators they interface with include:

- I2C based inertial measurement units

- DC linear actuators

- Piezoresistive force sensors

- 4-20ma inputs

The boards are controlled by the STM32 family of microcontrollers. The firmware is developed in C.

Please feel free to ask me anything about our controls system. The machine is developing rapidly.